Ho thothomela hali-motor tsa synchronous tse sa feleng tsa makenetehaholo-holo e tsoa likarolong tse tharo: lerata la aerodynamic, vibrate ea mochine, le vibrate ea motlakase. Lerata la aerodynamic le bakoa ke liphetoho tse potlakileng tsa khatello ea moea ka har'a enjene le khohlano lipakeng tsa khase le sebopeho sa enjene. Ho sisinyeha ha mochini ho bakoa ke ho feto-fetoha ha nako le nako ha li-bearings, bofokoli ba geometri, le ho se leka-lekane ha rotor shaft. Ho sisinyeha ha motlakase ho bakoa ke ho tsosoa ha motlakase, 'me lekhalo la khoheli la moea le sebetsa mokokotlong oa stator, le baka deformation ea radial ea stator, e fetisetsoang ho casing ea enjene ebe e hlahisa lerata. Leha karolo ea tangential ea lekhalo la moea la matla a khoheli e le nyane, e ka baka torque ripple le ho thothomela ha koloi. Ka propulsion eali-motor tsa synchronous tse sa feleng tsa makenete, ho tsosoa ha motlakase ke mohloli o ka sehloohong oa ho thothomela.

Mokhahlelong oa pele oa moralo oali-motor tsa synchronous tse sa feleng tsa makenete, ka ho theha mofuta oa karabelo ea vibrate, ho sekaseka thepa ea ho hlasimolla ha motlakase le litšobotsi tse matla tsa sebopeho, ho bolela esale pele le ho lekola boemo ba lerata la vibrate, le ho ntlafatsa moralo oa ho thothomela, lerata la vibrate le ka fokotseha, ts'ebetso ea motor e ka ntlafatsoa; 'me potoloho ea nts'etsopele e ka khutsufatsoa.

Tsoelopele ea hajoale ea lipatlisiso e ka akaretsoa ka likarolo tse tharo:

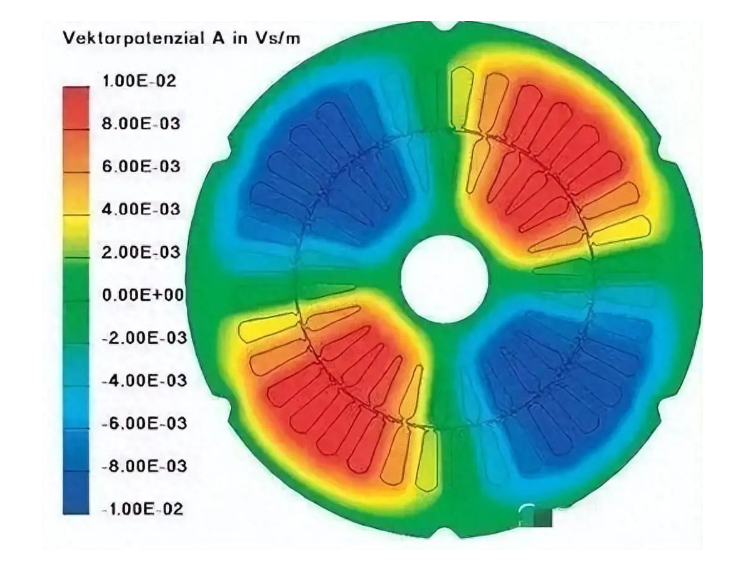

1. Patlisiso mabapi le ho tsosoa ha motlakase: Ho tsosoa ha motlakase ke sesosa sa mantlha sa ho thothomela, 'me lipatlisiso esale li tsoela pele ka lilemo tse ngata. Patlisiso ea pejana e kenyelelitse ho baloa ho ajoa ha matla a makenete a motlakase ka har'a li-motor le ho fumana mekhoa ea tlhahlobo ea matla a radial. Lilemong tsa morao tjena, mekhoa ea papiso ea lintlha le tlhahlobo ea lipalo e sebelisitsoe haholo, 'me litsebi tsa malapeng le tsa kantle ho naha li ithutile ka tšusumetso ea tlhophiso e fapaneng ea poleiti ho torque ea li-motor synchronous motors.

2. Lipatlisiso mabapi le litšoaneleho tsa mekhoa ea sebopeho: Litšobotsi tsa modal tsa sebopeho li amana haufi-ufi le karabelo ea eona ea ho sisinyeha, haholo-holo ha maqhubu a ho tsosoa a le haufi le maqhubu a tlhaho a sebopeho, resonance e tla etsahala. Litsebi tsa malapeng le tsa kantle ho naha li ithutile litšobotsi tsa sebopeho sa litsamaiso tsa motor stator ka liteko le lipapiso, ho kenyeletsoa lintlha tse amang maqhubu a modal joalo ka thepa, elastic modulus, le paramente ea meralo.

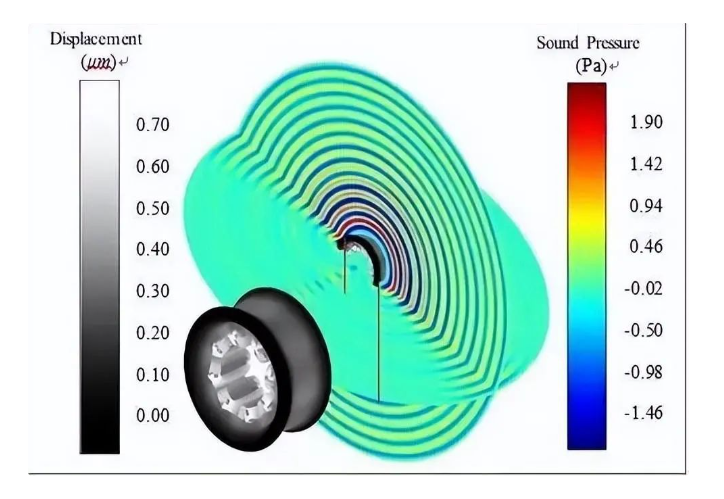

3. Patlisiso mabapi le Karabelo ea Vibration tlas'a Phatlalatso ea Motlakase: Karabelo ea ho thothomela ea enjene e bakoa ke ho tsosoa ke motlakase o sebetsang ho meno a stator. Bafuputsi ba ile ba hlahlobisisa kabo ea spatiotemporal ea matla a makenete a motlakase, ba kenya thabo ea motlakase ka har'a sebopeho sa motor stator, mme ba fumana lipalo tsa lipalo le liphetho tsa liteko tsa karabelo ea vibrate. Bafuputsi ba boetse ba batlisisa tšusumetso ea coefficient ea damping ea thepa ea khetla karabelong ea ho thothomela.

Nako ea poso: Mar-06-2024