1.Ke mekhoa efe e atisang ho sebelisoa ea ho pholisa bakeng sa likoloi tsa likoloi tsa motlakase?

Likoloi tsa motlakase (EVs) li sebelisa litharollo tse fapaneng tsa ho pholisa ho laola mocheso o hlahisoang ke li-motor. Litharollo tsena li kenyelletsa:

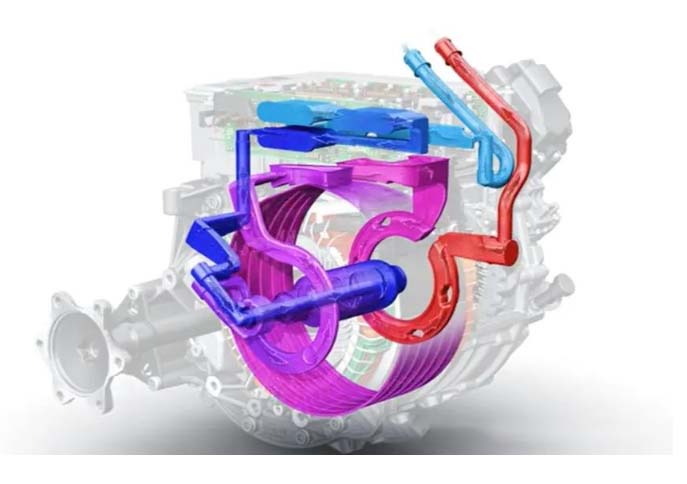

Liquid Cooling: Tsamaisa mokelikeli o pholisang ka likanale tse ka hare ho enjene le likarolo tse ling. E thusa ho boloka mocheso o nepahetseng oa ts'ebetso, e leng se bakang ts'ebetso e phahameng ea mocheso oa ho qhala ha o bapisoa le pholileng ea moea.

Pholiso ea Moea: Moea o potoloha holim'a bokaholimo ba enjene ho felisa mocheso. Le hoja ho pholisa moea ho le bonolo ho bile ho le bobebe, ho sebetsa ha eona ho ka 'na ha se be hantle joaloka ho pholile ha metsi, haholo-holo lits'ebetsong tse sebetsang hantle kapa tse boima.

Ho Pholisa Oli: Oli e monya mocheso ho tsoa enjeneng ebe e potoloha ka har'a sistimi e pholileng.

Pholiso e Otlolohileng: Ho pholisa ka ho toba ho bolela tšebeliso ea lipholisa kapa lihatsetsi ho pholisa ka ho toba li-winding tsa stator le rotor core, ho laola mocheso ka katleho lits'ebetsong tse sebetsang hantle haholo.

Lisebelisoa tsa phetoho ea Phase (PCM): Lisebelisoa tsena li monya le ho lokolla mocheso nakong ea phetoho ea mekhahlelo, li fana ka taolo e sa fetoheng ea mocheso. Li thusa ho laola mocheso le ho fokotsa tlhoko ea mekhoa e sebetsang ea ho pholisa.

Lisebelisoa tsa mocheso: Lisebelisoa tsa mocheso li ka fetisetsa mocheso pakeng tsa litsamaiso tse fapaneng tsa mokelikeli, joalo ka ho fetisetsa mocheso ho tloha sehatsetsing sa enjene ho ea ho hitara ea khabin kapa sistimi ea ho futhumatsa betri.

Khetho ea tharollo ea pholileng e itšetlehile ka lintlha tse kang moralo, litlhoko tsa ts'ebetso, litlhoko tsa tsamaiso ea mocheso, le tšebeliso e reretsoeng ea likoloi tsa motlakase. Likoloi tse ngata tsa motlakase li kopanya mekhoa ena ea ho pholisa ho ntlafatsa ts'ebetso le ho netefatsa bophelo bo bolelele ba koloi.

2.Ke litharollo life tse tsoetseng pele tsa ho pholisa?

Mekhahlelo e 'meli ea Pholiso ea Phase: Litsamaiso tsena li sebelisa lisebelisoa tsa phetoho ea mohato (PCM) ho monya le ho lokolla mocheso ha o tloha ho metsi ho ea ho khase. Sena se ka fana ka litharollo tse pholileng tse sebetsang hantle le tse kopaneng bakeng sa likarolo tsa koloi ea motlakase, ho kenyeletsoa li-motor le lisebelisoa tsa motlakase tsa motlakase.

Pholiso ea Microchannel: Pholiso ea Microchannel e bolela tšebeliso ea likanale tse nyane ka har'a sistimi e pholisang ho matlafatsa phetisetso ea mocheso. Theknoloji ena e ka ntlafatsa bokhoni ba ho senya mocheso, ho fokotsa boholo le boima ba likarolo tse pholileng.

Pholiso ea Liquid ka ho Otloloha: Ho pholisa metsi ka kotloloho ho bolela ho potoloha ka kotloloho ha sepholi ka enjene kapa karolo e 'ngoe e fehlang mocheso. Mokhoa ona o ka fana ka taolo e nepahetseng ea mocheso le ho tlosa mocheso o sebetsang hantle, o thusang ho ntlafatsa ts'ebetso ea tsamaiso eohle.

Thermoelectric Cooling: Thermoelectric e ka fetola phapang ea mocheso hore e be voltage, e fana ka tsela ea ho pholisa sebakeng se itseng libakeng tse itseng tsa likoloi tsa motlakase. Theknoloji ena e na le monyetla oa ho sebetsana le libaka tse hotspots le ho ntlafatsa bokhoni ba ho pholisa.

Liphaephe tsa Mocheso: Liphaephe tsa mocheso ke lisebelisoa tse fetisang mocheso tse sebelisang mokhoa oa phetoho oa mohato bakeng sa ho fetisa mocheso hantle. E ka kopanngoa le likarolo tsa koloi ea motlakase ho ntlafatsa ts'ebetso ea pholileng.

Active Thermal Management: Li-algorithms tsa taolo e tsoetseng pele le li-sensor li sebelisoa ho fetola litsamaiso tse pholileng ho ipapisitsoe le data ea nako ea nnete ea mocheso. Sena se netefatsa ts'ebetso e nepahetseng ea ho pholisa ha ho ntse ho fokotsa tšebeliso ea matla.

Lipompompo tsa Pholiso tsa Lebelo tse feto-fetohang: Sistimi ea ho pholisa ea Tesla e ka sebelisa lipompo tsa lebelo tse fapaneng ho fetola sekhahla sa phallo ea pholiso ho latela litlhoko tsa mocheso, ka hona e ntlafatsa ts'ebetso ea pholiso le ho fokotsa tšebeliso ea matla.

Hybrid Cooling Systems: Ho kopanya mekhoa e mengata ea ho pholisa, joalo ka ho pholile ha metsi le ho pholile ho fetola karolo kapa ho pholile ha microchannel, ho ka fana ka tharollo e pharaletseng bakeng sa ho ntlafatsa ho qhala ha mocheso le tsamaiso ea mocheso.

Hoa lokela ho hlokomeloa hore ho fumana lintlha tsa morao-rao mabapi le theknoloji ea morao-rao ea ho pholisa likoloi tsa motlakase, ho kgothaletswa ho shebana le lingoliloeng tsa indasteri, lipampiri tsa lipatlisiso le baetsi ba likoloi tsa motlakase.

3. Ke mathata afe ao litharollo tsa ho pholisa enjene tse tsoetseng pele li tobanang le tsona?

Ho rarahana le Litšenyehelo: Tšebeliso ea lisebelisoa tse tsoetseng pele tsa ho pholisa tse kang ho pholisa metsi, lisebelisoa tsa phetoho ea mohato, kapa ho pholisa ka microchannel ho tla eketsa ho rarahana ha moralo oa koloi ea motlakase le mekhoa ea ho etsa. Ho rarahana hona ho tla lebisa litšenyehelong tse phahameng tsa tlhahiso le tlhokomelo.

Ho kopanya le ho paka: Ho kopanya lisebelisoa tse pholileng tse tsoetseng pele sebakeng se moqotetsane sa mehaho ea likoloi tsa motlakase ho thata. Ho netefatsa sebaka se loketseng bakeng sa likarolo tse pholileng le ho laola litsela tsa ho potoloha ha mokelikeli ho ka ba thata haholo ntle le ho ama sebopeho sa koloi kapa sebaka.

Tlhokomelo le Litokiso: Lits'ebetso tsa ho pholisa tse tsoetseng pele li ka hloka tlhokomelo le litokiso tse khethehileng, tse ka bang thata ho feta litharollo tsa setso tsa ho pholisa. Sena se ka eketsa litšenyehelo tsa tlhokomelo le tokiso bakeng sa beng ba likoloi tsa motlakase.

Tšebeliso ea Matla le Matla: Mekhoa e meng e tsoetseng pele ea ho pholisa, joalo ka ho pholisa metsi, e ka hloka matla a eketsehileng bakeng sa ts'ebetso ea pompo le ho potoloha ha metsi. Ho fumana ho leka-lekana pakeng tsa ho ntlafatsa ts'ebetso ea ho pholisa le ho eketsa tšebeliso ea matla ke phephetso.

Tšebelisano 'moho le Lintho: Ha ho khethoa lisebelisoa bakeng sa lisebelisoa tse tsoetseng pele tsa ho pholisa, ho tlameha ho nahanoa ka hloko ho netefatsa hore li lumellana le li-coolants, lubricant le maro a mang. Ho se lumellane ho ka baka kutu, ho lutla kapa mathata a mang.

Ketane ea Tlhahiso le ea Thekiso: Kamohelo ea litheknoloji tse ncha tsa ho pholisa ho ka 'na ha hloka liphetoho mekhoeng ea tlhahiso le thekisong ea thepa, e leng se ka bakang tieho kapa mathata a tlhahiso.

Ho tšepahala le Bophelo bo Bolelele: Ho netefatsa ho ts'epahala ha nako e telele le ho tšoarella ha litharollo tse tsoetseng pele tsa ho pholisa ho bohlokoa. Ho se sebetse hantle tsamaisong ea ho pholisa ho ka baka mocheso o feteletseng, ho senyeha ha ts'ebetso, esita le ho senya likarolo tsa bohlokoa.

Tšusumetso ea Tikoloho: Tlhahiso le ho lahla likarolo tsa tsamaiso ea ho pholisa e tsoetseng pele (joaloka lisebelisoa tsa phetoho ea mokhahlelo kapa maro a khethehileng) ho ka ba le tšusumetso tikolohong 'me ho hloka ho nahanoa.

Ho sa tsotellehe mathata ana, mosebetsi o amanang le lipatlisiso le nts'etsopele o ntse o khothaletsoa ka matla, 'me nakong e tlang, litharollo tsena tse tsoetseng pele tsa ho pholisa li tla sebetsa, li sebetse hantle, li be li tšepahale. Ka tsoelo-pele ea theknoloji le ho bokella phihlelo, liphephetso tsena li tla fokotseha butle-butle.

4.Ke lintlha life tse lokelang ho nahanoa ka moralo oa sistimi ea ho futhumatsa koloi?

Moloko oa Mocheso: Utloisisa tlhahiso ea mocheso oa enjene tlas'a maemo a fapaneng a ts'ebetso. Sena se kenyelletsa lintlha tse kang tlhahiso ea matla, mojaro, lebelo le nako ea ts'ebetso.

Mokhoa oa ho Pholisa: Khetha mokhoa o nepahetseng oa ho pholisa, joalo ka pholileng ea mokelikeli, ho pholisa moea, lisebelisoa tsa ho fetola karolo, kapa ho pholile ha motsoako. Nahana ka melemo le melemo ea mokhoa o mong le o mong ho latela litlhoko tsa ho senya mocheso le sebaka se fumanehang sa motlakase.

Libaka tsa Taolo ea Thermal: Khetholla libaka tse ikhethileng ka har'a enjene tse hlokang ho pholisoa, joalo ka stator windings, rotor, bearings le likarolo tse ling tsa bohlokoa. Likarolo tse fapaneng tsa enjene li ka hloka mekhoa e fapaneng ea ho pholisa.

Heat Transfer Surface: Rala libaka tse fetisoang hantle tsa mocheso, joalo ka mapheoana, likanale kapa lipeipi tsa mocheso, ho netefatsa hore mocheso o tsoa ho enjene ho ea sebakeng se phodileng.

Khetho ea ho Pholisa: Khetha sepholi se loketseng kapa mokelikeli o tsamaisang mocheso ho fana ka ho monya mocheso hantle, ho o fetisa le ho o lokolla. Nahana ka lintlha tse kang conductivity ea mocheso, ho lumellana le thepa, le phello tikolohong.

Sekhahla sa Phallo le Potoloho: Etsa qeto ea sekhahla sa phallo ea pholiso e hlokahalang le mokhoa oa ho potoloha ho tlosa mocheso oa enjine ka botlalo le ho boloka mocheso o tsitsitseng.

Pompo le Boholo ba Fane: Etsa qeto ka ho utloahalang boholo ba pompo e pholileng le fene ho netefatsa phallo e lekaneng ea pholiso le moea o pholileng bakeng sa ho pholisa hantle, ha u ntse u qoba tšebeliso e feteletseng ea matla.

Taolo ea Mocheso: Kenya ts'ebetsong mokhoa oa ho laola mocheso oa motlakase ka nako ea sebele le ho fetola liparamente tsa ho pholisa ka nepo. Sena se ka 'na sa hloka tšebeliso ea lisebelisoa tsa mocheso, li-controller le li-actuator.

Ho Kopana le Litsamaiso Tse Ling: Etsa bonnete ba ho lumellana le ho hokahana le litsamaiso tse ling tsa likoloi, joalo ka litsamaiso tsa taolo ea mocheso oa betri le lisebelisoa tsa ho pholisa tsa elektroniki, ho theha leano le akaretsang la taolo ea mocheso.

Lisebelisuoa le Tšireletso ea Corrosion: Khetha lisebelisoa tse lumellanang le se pholisang se khethiloeng 'me u netefatse hore ho nkoa mehato e nepahetseng ea ho thibela ho bola ho thibela ho senyeha ha nako e ntse e ea.

Litšitiso tsa Sebaka: Nahana ka sebaka se fumanehang ka har'a koloi le moralo oa enjene ho etsa bonnete ba hore ho sebetsa ka katleho tsamaiso ea ho pholisa ntle le ho ama likarolo tse ling kapa moralo oa koloi.

Ho tšepahala le ho Hlokahala: Ha ho etsoa moralo oa mokhoa oa ho pholisa, ho lokela ho nahanoa ka botšepehi 'me mekhoa ea ho pholisa e sa sebetseng kapa e sa sebetseng e lokela ho sebelisoa ho netefatsa ts'ebetso e bolokehileng haeba karolo e hloleha.

Teko le netefatso: Etsa tlhahlobo e felletseng le netefatso ho netefatsa hore sistimi ea ho pholisa e fihlela litlhoko tsa ts'ebetso mme e khona ho laola mocheso ka nepo tlasa maemo a fapaneng a ho khanna.

Bokamoso ba Scalability: Nahana ka tšusumetso e ka bang teng ea lintlafatso tsa enjene nakong e tlang kapa liphetoho tsa moralo oa koloi tšebetsong ea sistimi ea ho pholisa.

Moralo oa litsamaiso tse futhumatsang tsa makoloi o kenyelletsa mekhoa e fapaneng, e kopanyang boiphihlelo ba boenjiniere ho matla a mocheso, mechini ea mokelikeli, mahlale a thepa le lisebelisoa tsa elektroniki.

Nako ea poso: Mar-06-2024